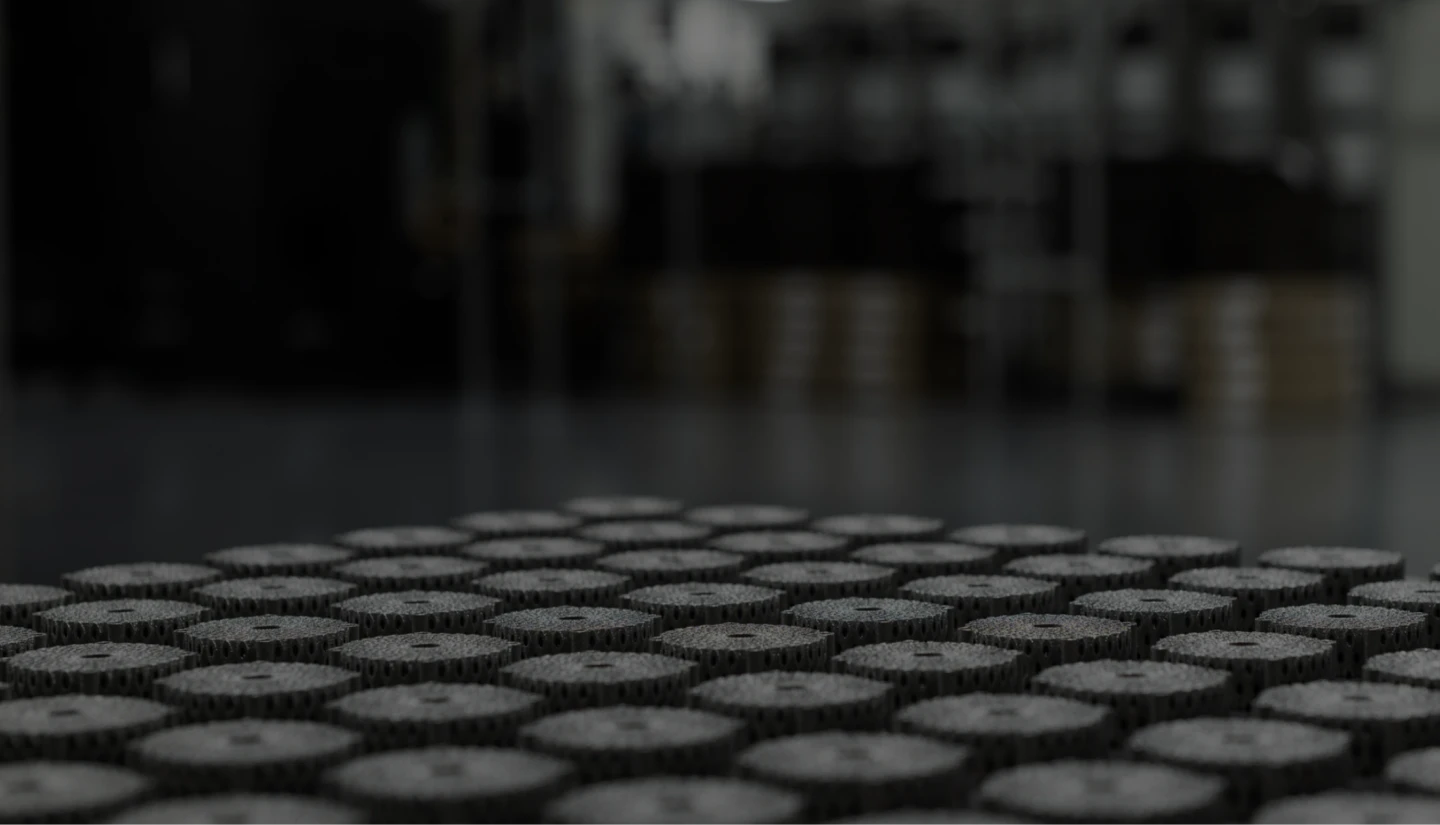

Create Superior Products by Unlocking Next Generation Design Freedom

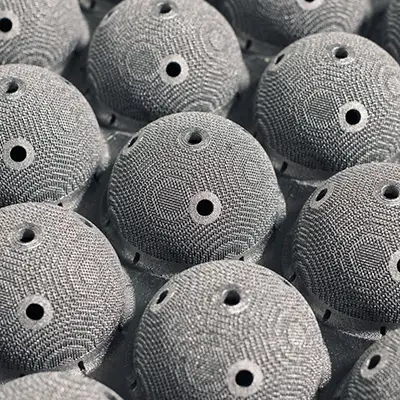

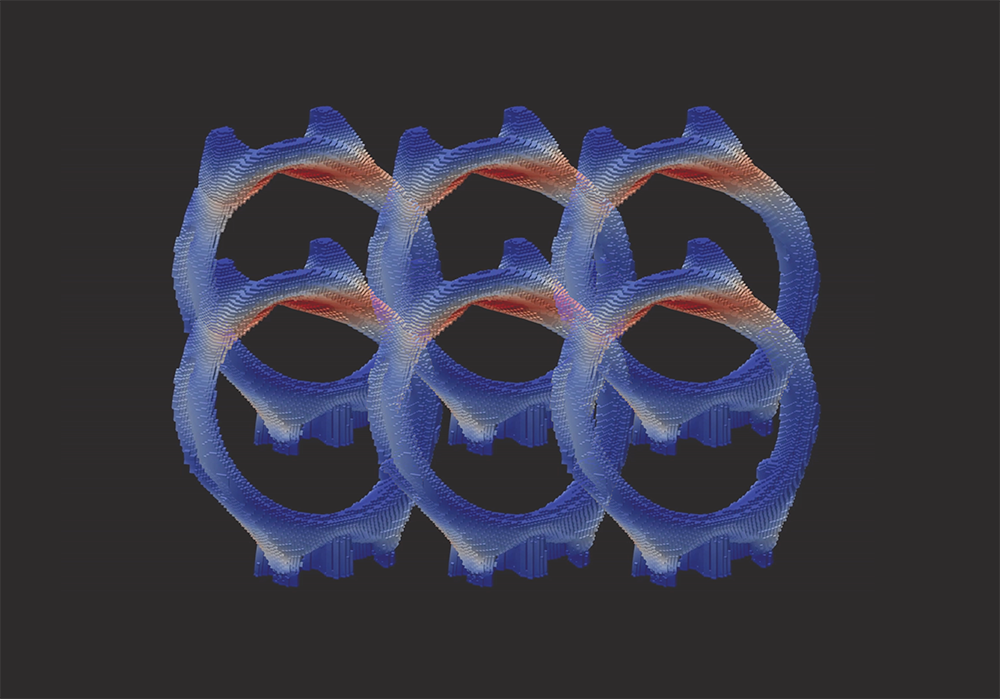

VulcanForms empowers innovators with advanced manufacturing capabilities, enabling complex geometries, optimized performance, and material efficiency at scale. From lightweight structures to intricate components, our digital production system removes traditional design constraints, transforming ideas into reality.