We print metal parts. No tooling. No compromise. No limits.

GEN 3: The Most Productive Metal Printer.

Designed and built by VulcanForms, GEN 3 offers industrial-scale metal laser powder bed fusion with a 40kW laser system (75 lasers at 550W). It prints mission-critical metal parts with unmatched speed, density, and repeatability. It runs 24/7, requires no tooling, and delivers production-quality parts at scale.

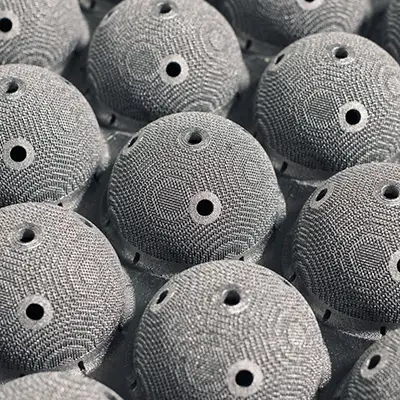

Parts That Meet the Highest Standards.

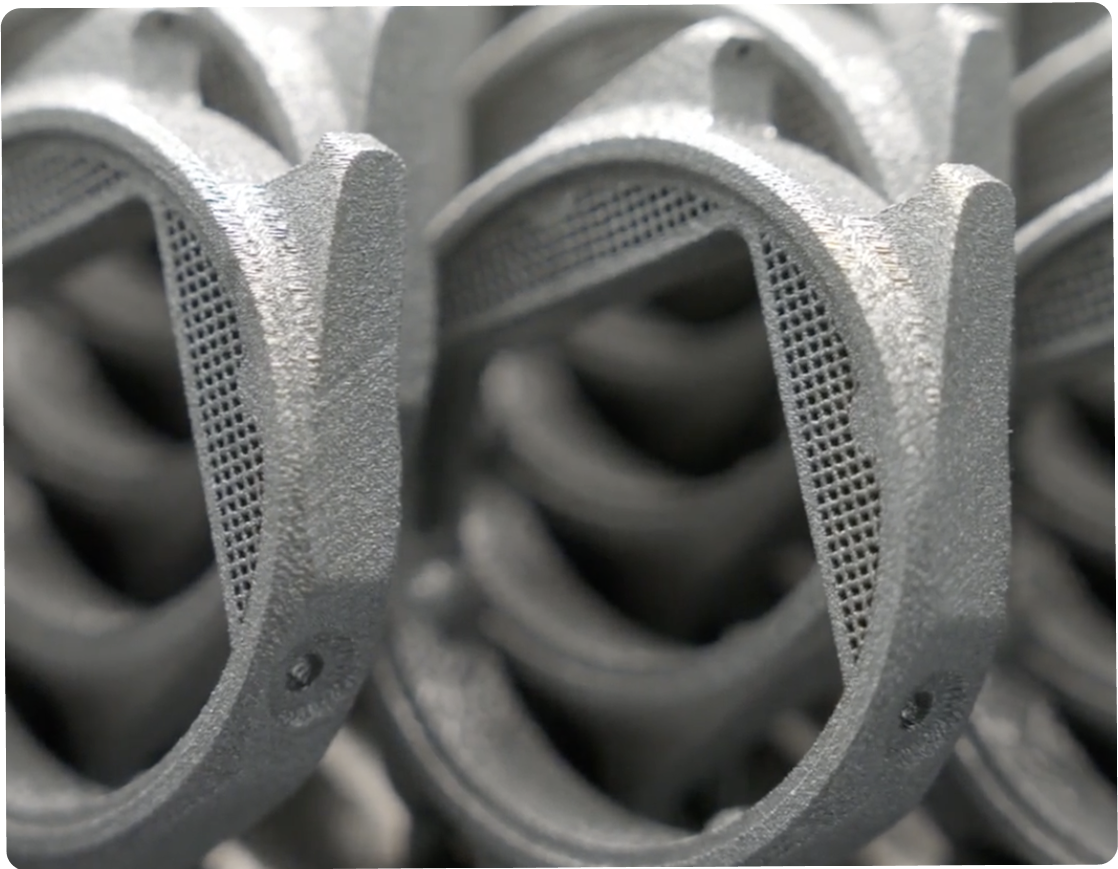

GEN 3 prints fully dense metal parts with micron-level precision and exceptional surface finish. It delivers high-resolution detail, high-strength materials, and unmatched mechanical performance.

Quality

Consistent, high-quality parts produced at volume without sacrificing speed or reliability.

Resolution

Micron-level precision enables sharp edges, thin walls, and fine surface finish.

Density

Fully dense parts deliver mechanical strength that rivals cast, forged, or machined components.

More Output. Less Cost

GEN 3 lowers per-part cost by maximizing machine output and minimizing material waste.

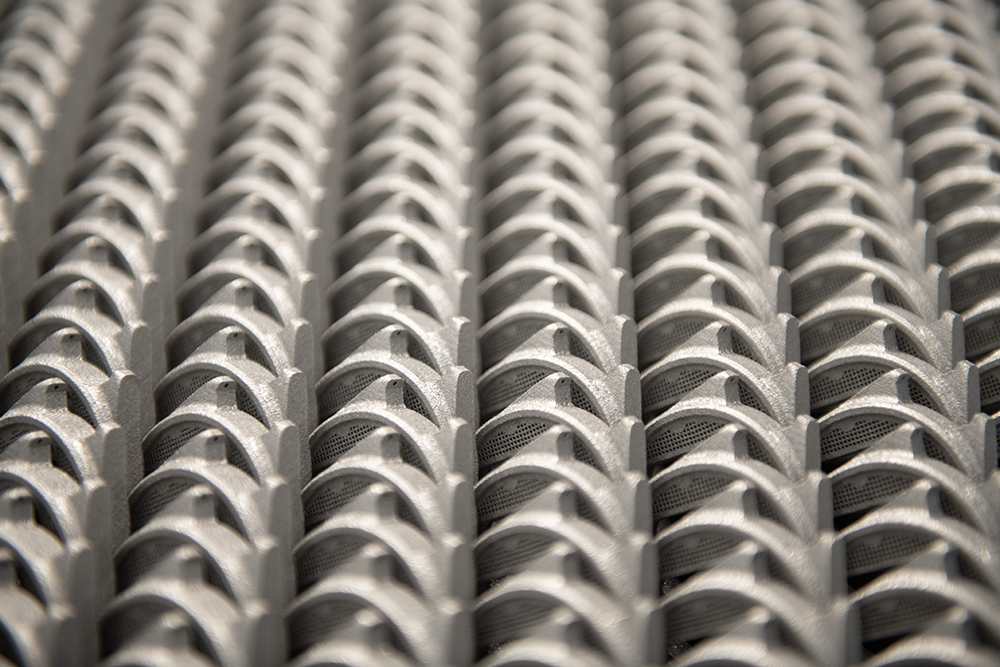

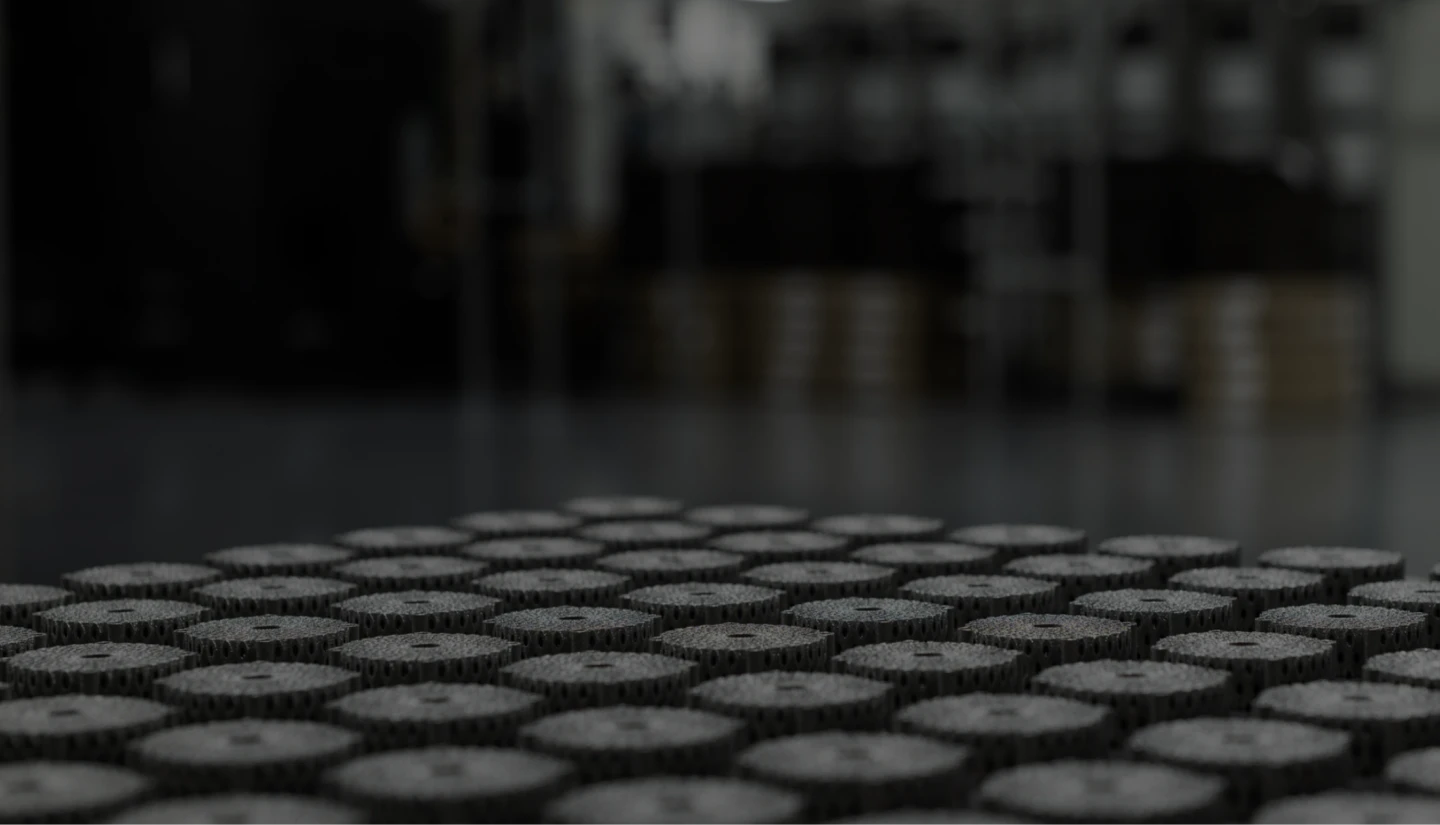

More Parts per Build

Tightly packed layouts maximize each build and reduce print cycles and machine time.

Lower Cost per Part

Tooling is eliminated and waste reduced by reclaiming powder and reusing build plates.

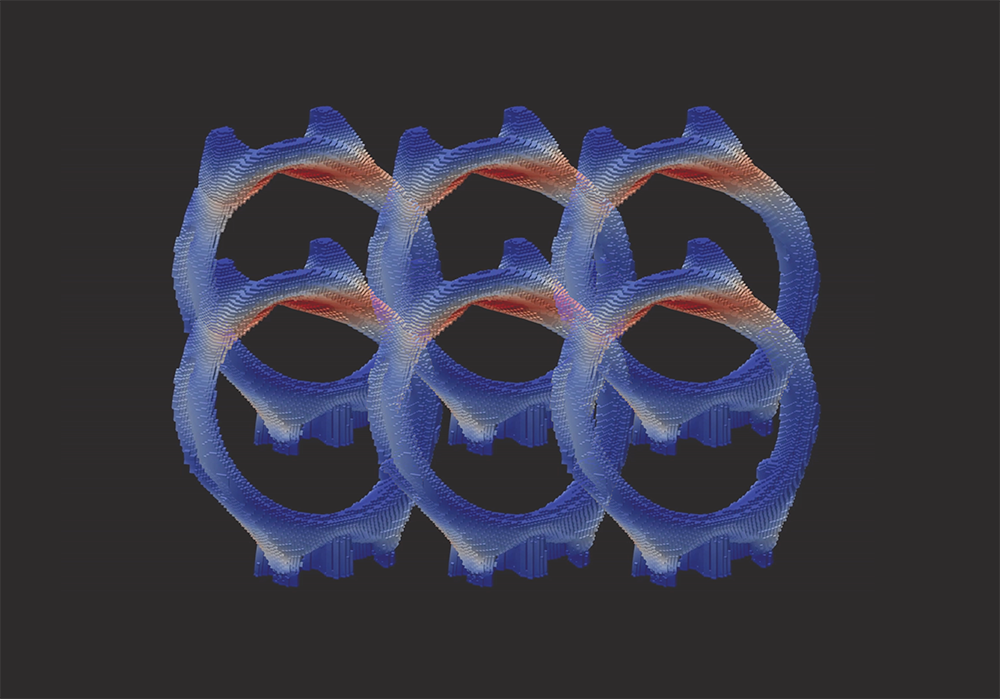

Full Visibility. Zero Surprises.

A centralized control system monitors every GEN 3 printer in real time, ensuring quality, uptime, and traceability at scale.

Explore More:

Machining, Automation, & Assembly

High-precision machining with tight tolerances, smooth surface finishes, and reliable dimensional control. Our subtractive capabilities are built for production scale, supporting everything from critical features to final part finishing.

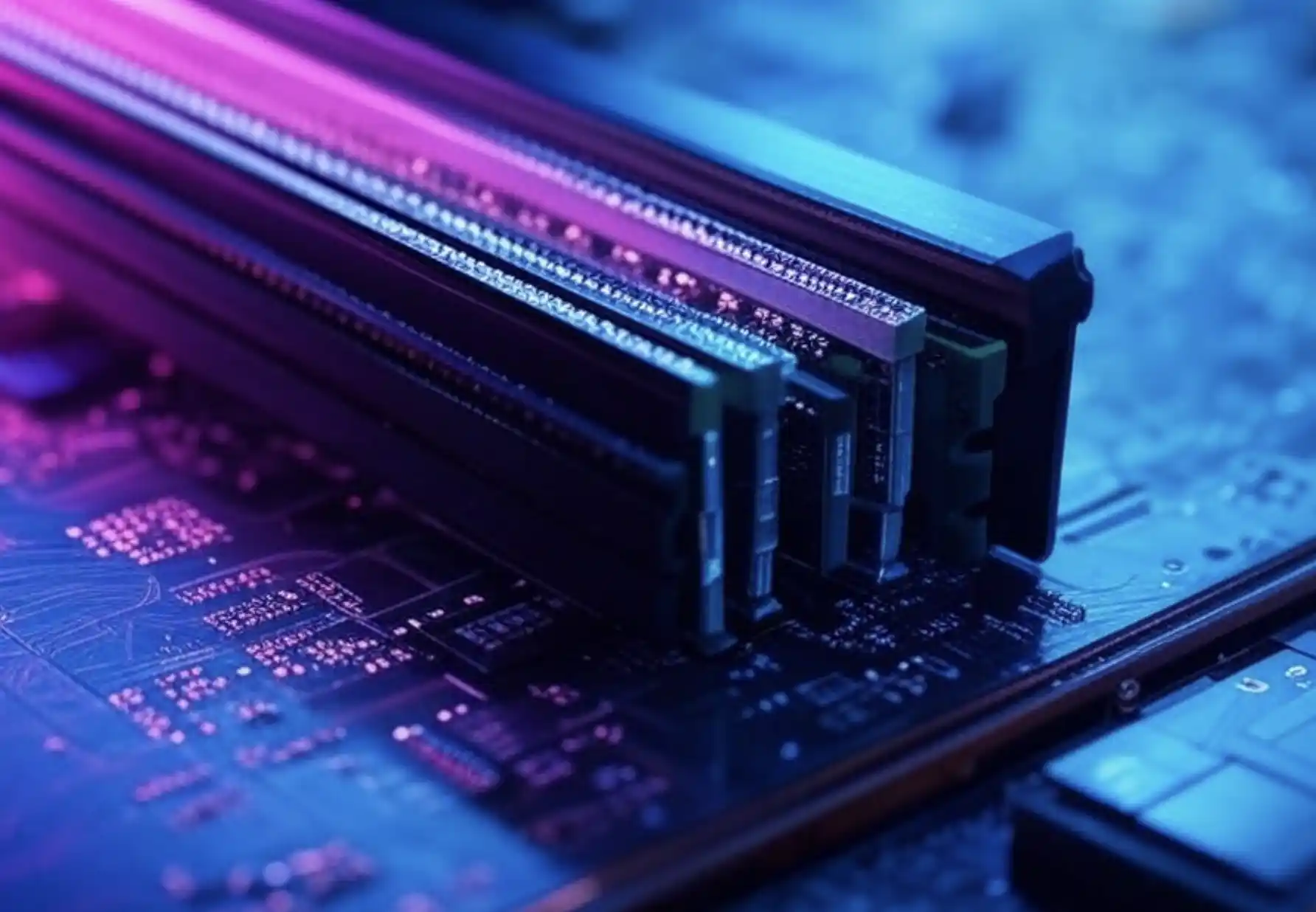

AI-Powered Software

AI-driven software supports every stage of production, from build preparation and slicing to in-process monitoring and quality control. This ensures predictable outcomes, shorter lead times, and complete traceability.

Let's build. Request a demo.

Learn how VulcanForms can help you innovate faster with digital manufacturing at scale.