Building the Capacity America Needs

Since our inception, our focus has been on a single priority. Build advanced metal manufacturing capacity in the United States at a scale, quality level, and degree of integration that does not exist today. Everything else flows from that goal.

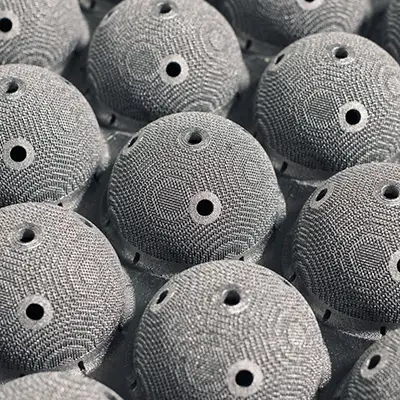

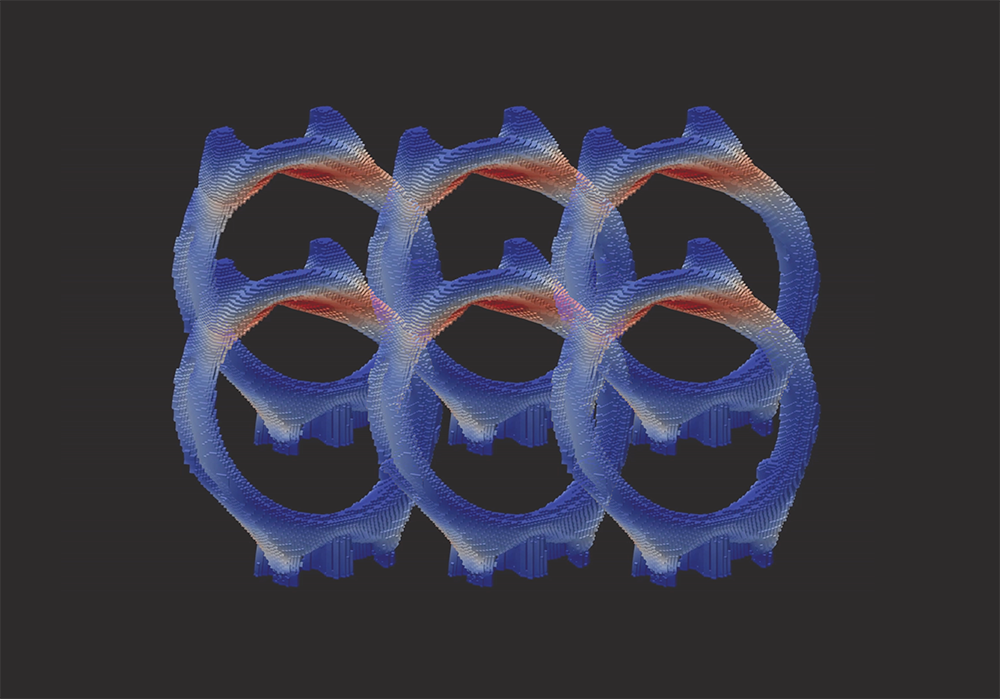

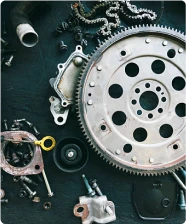

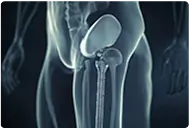

Reaching this point has meant working through challenges across physics, process control, automation, and supply chain reliability. It has also required proving that advanced manufacturing can support sustained production work with consistent results, not short runs or limited builds. That proof is now visible across aerospace, defense, medical, consumer, industrial, and several adjacent markets.

Demand for production parts continues to grow. We are supporting programs for multiple Fortune 500 manufacturers across these sectors, and many of these customers are planning for long production horizons with an expectation that their partners can scale confidently. This is where our integrated platform shows its strength. By combining raw materials, additive manufacturing, machining, and digital control within a vertically integrated factory, we can deliver qualified parts with fewer handoffs and tighter command of the entire manufacturing chain.

Our expansion plans, beginning with the build out of VulcanThree and extending to additional U.S. production facilities, are designed to match this rising demand.

As part of this broader expansion, we are also planning for the VulcanForms Campus, a multi-facility environment that unites material production, additive manufacturing, post-processing, and machining within one integrated footprint. The Campus includes dedicated powder production buildings where titanium, nickel, aluminum, copper, and other metal alloys are processed into powder. From there, material is routed into adjacent manufacturing buildings organized around individual material families to support consistent quality and scalable production. Alongside VulcanOne in Devens and VulcanTwo in Newburyport, the Campus represents the next stage of scaling capacity while maintaining the quality, repeatability, and reliability our customers expect.

This effort is part of a broader shift taking place in the United States. Companies are bringing critical production back home and reducing reliance on offshore manufacturing for strategic metals and components. We see this across our customer base. More teams are designing with domestic production in mind from the beginning. It is a practical response to risk mitigation, reliability improvement, and long-term national interest.

At a fundamental level, this shift reflects something simple from a first principles approach to manufacturing. A metal atom should not have to travel around the world multiple times to become a finished part. Today, many critical components depend on supply chains that stretch across multiple continents before a single piece reaches the customer. That distance adds cost, risk, delay, and variability at every step. Scaling capacity and applying modern technology and process minimization reduces that complexity and gives customers a more stable and predictable path from raw material to qualified part.

Our goal remains straightforward. Build the most capable metal manufacturing platform in the world. Deliver on customer programs at production scale. Support the broader industrial base with the capacity it needs to grow. And continue raising the standard for what American advanced manufacturing can deliver.

Thank you to our customers, partners, and the entire VulcanForms team. The work ahead is significant, and we remain committed to world-class execution and rebuilding America’s leadership in advanced manufacturing.

Latest News

VulcanForms additively manufactures 2 kN rocket thruster designed by LEAP 71’s Noyron AI software

May 13, 2025

From Tesla to Metal 3D Printing: VulcanForms’ New CEO Shares His Blueprint

October 18, 2024

VulcanForms appoints Kevin Kassekert as CEO & Jay Martin as President

September 20, 2024